Using Advanced Technologies to Detect and Measure Methane Emissions in the Biogas Industry

Across the UK and globally, communities are generating more organic waste than ever before — from agricultural byproducts and livestock manure to discarded food. Left unmanaged, this waste decomposes and produces methane, a potent greenhouse gas. Managed correctly, however, it can be transformed into biogas, a renewable energy source that powers homes, fuels vehicles, and reduces landfill use.

Anaerobic digestion (AD) is at the heart of this process. Organic material is broken down by bacteria in oxygen-free environments, creating a mix of biogas and digestate (which can be used as fertiliser). Biogas can be upgraded into biomethane, or Renewable Natural Gas (RNG), which can be injected into the gas grid or used for heat, electricity, and even sustainable plastics.

Yet despite its environmental benefits, methane from biogas facilities must still be tightly controlled. Even small leaks can harm air quality, impact safety, and erode sustainability gains.

Why Leak Detection Matters

Biogas sites — from digesters and pumps to roof seals and pipelines — have multiple potential leak points. Methane escapes are often invisible and can be difficult to locate using conventional inspection methods.

That’s where Inspectahire comes in. With decades of experience in advanced inspection and monitoring, we provide the specialist technology and know-how to detect, locate, and measure methane emissions quickly, safely, and with pinpoint accuracy.

Optical Gas Imaging: Seeing the Invisible

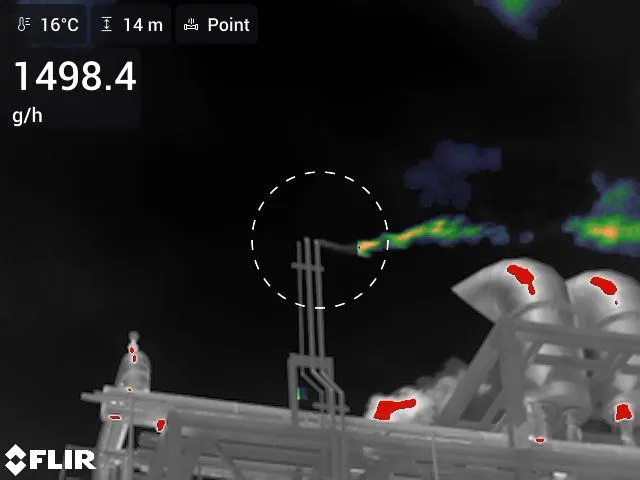

Inspectahire deploys Optical Gas Imaging (OGI) technology, including the FLIR G-Series cooled infrared cameras, which are engineered to detect specific gases such as methane. These cameras filter the infrared spectrum to the wavelength where methane absorbs light, allowing operators to visualise leaks in real-time — turning an invisible hazard into something you can see, track, and fix.

Key advantages of OGI:

- Real-time visualisation – Live video feed shows leaks as smoke-like plumes, enabling immediate source pinpointing.

- Wide-area scanning – Quickly covers pumps, valves, roof seals, and pipelines without physical contact.

- High Sensitivity Mode – Detects even the smallest emissions, improving accuracy by up to 10× compared to traditional LDAR (Leak Detection and Repair) methods.

- ATEX-compliant operation – Safe deployment in hazardous zones.

From Detection to Measurement: QOGI Technology

Our service now integrates Quantitative Optical Gas Imaging (QOGI) — a major leap forward in emissions management. Using advanced analytics embedded in FLIR G-Series cameras such as the G620, QOGI not only detects a leak but also quantifies the emission rate directly from a safe distance.

Why this matters:

- Immediate data for environmental reporting and compliance.

- Ability to prioritise repairs based on leak size and financial impact.

- Integration into maintenance schedules for targeted interventions.

Inspectahire in Action

We regularly work with AD plant operators, utilities, and industrial clients to:

- Survey sites for methane emissions without interrupting operations.

- Pinpoint exact leak locations and measure their size.

- Support repair planning with detailed reports and imagery.

- Verify repair success through post-fix inspection.

This combination of rapid mobilisation, specialist technology, and trained technicians helps operators maintain environmental compliance, reduce greenhouse gas emissions, and improve plant safety.

Conclusion

Biogas and RNG will continue to play a vital role in the UK’s energy mix and the wider shift to renewable sources. But to truly deliver on their environmental promise, operators must manage methane emissions with precision.

Inspectahire’s OGI and QOGI services give you that precision. We help you see the invisible, measure what matters, and take action quickly — keeping your operation compliant, efficient, and sustainable.